CNC Machining and Turning

Computer Numerical Control (CNC) machining is a highly advanced manufacturing process that uses pre-programmed computer software to control machinery movement. This technology enables high precision, repeatability, and efficiency in producing complex parts from metals, plastics, and other materials. The capabilities of CNC machining are defined by the types of machines and tools available, their specifications, and their adaptability to various tasks.

HAAS CNC: 5 Axis, 3 Axis, High-Speed, Multi-Axis Precision Machines

- 5 AXIS CNC Machining - HAAS UMC 1000SS, UMC 750M

- 3 AXIS CNC Machining - HAAS VF5 and VF2

- HWAHEON Hi-Tech 200A Turning Center

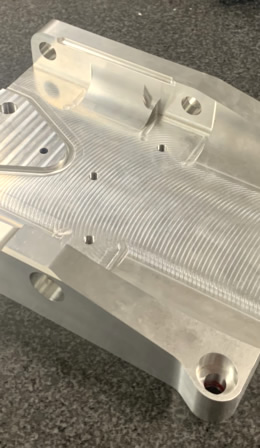

The 5-axis CNC machining capabilities of the HAAS UMC-1000SS offer exceptional precision and versatility for complex manufacturing applications. Designed for high-speed machining, the UMC-1000SS integrates simultaneous 5-axis movement, enabling the efficient production of intricate parts with minimal setups. Its robust construction and advanced features, such as a high-speed spindle, dynamic toolpath optimization, and direct-drive rotary axes, ensure exceptional accuracy and surface finish. This machine is ideal for industries like aerospace, automotive, and medical device manufacturing, where precision and efficiency are paramount. The HAAS UMC-1000SS also boasts an intuitive user interface with HAAS's proprietary control system, making it user-friendly and reducing operator learning curves, while its large work envelope accommodates a wide range of part sizes and configurations.

The HAAS VF-5 is a versatile vertical machining center renowned for its performance, reliability, and adaptability in precision manufacturing. Equipped with a robust 50-taper spindle (or optional 40-taper spindle), the VF-5 delivers exceptional cutting power and speed, making it suitable for a wide range of materials from aluminum to hardened steels. Its expansive work envelope provides ample space for medium to large-sized parts, making it a reliable choice for industries like aerospace, automotive, and general manufacturing. The machine features high-speed tool changes, advanced control software, and compatibility with 4th-axis and 5th-axis rotary tables, offering flexibility for complex geometries. With HAAS's user-friendly interface and customizable options, the VF-5 is designed to enhance productivity and reduce cycle times, making it an excellent solution for demanding production environments.

HWACHEON HI-TECH 200A: High-Performance Turning Center

The HWACHEON HI-TECH 200A turning center is an advanced machine specializing in high-performance turning, with an 83 mm turning capacity. Turning centers like the HWACHEON HI-TECH 200A are essential in machining cylindrical parts, performing operations like boring, threading, and grooving. This machine's versatility in creating rotational components, such as shafts, pulleys, and couplings, makes it integral to industries such as aerospace, automotive, and machinery manufacturing.

With its high precision and stability, the HWACHEON HI-TECH 200A excels in handling both large and small diameter parts with exacting standards, making it suitable for high-demand applications where repeatability and accuracy are critical. The 83 mm turning capacity is well-suited for a range of components, from delicate parts to robust, load-bearing elements. This machine's capabilities are essential for efficient, repeatable production of rotational parts, and its advanced technology supports consistent quality even in high-volume production.